Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

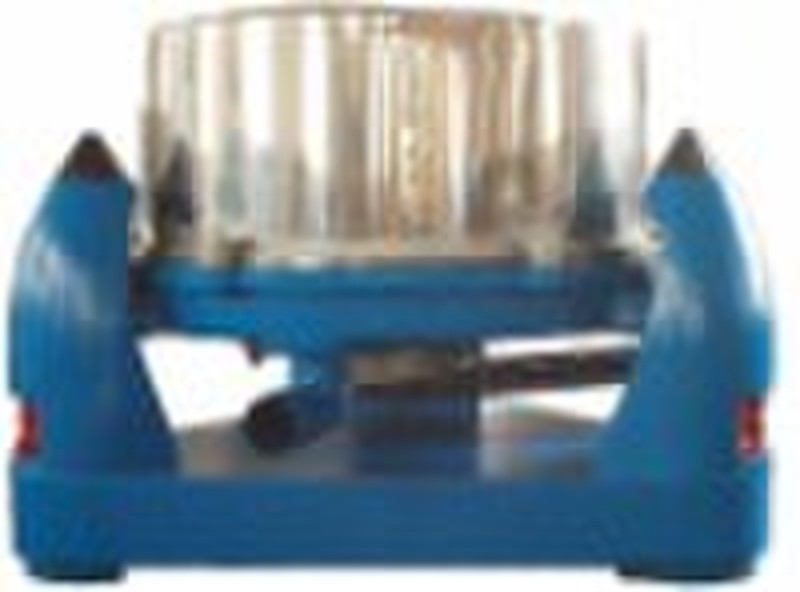

SS three-column discharge centrifugal machine

original price: 1 500 USD

Zhangjiagang, China

Production capacity:

5 Piece / Month

kathy lu

Contact person

Basic Information

How to Work Materials to be separated enter into the drum of the centrifuge rotating at high speed through a feeding tube, affected by the centrifugal force. The heavy phase material is sedimented to the outer layer of the drum, the light phase material is left on the inner layer of the drum. When sediment requirement is reached, operate the skimming device, the skimming pipe will enter into the drum, light phase material will skim from this pipe, the heavy phase material (filter cake) will remain on the drum, which will be discharged manually. Applications Apply to separating the suspended liquid contained particles, but also fibers, like plasters, bluestone, potassium chloride, borax, dyestuffs, pesticides, salts, gourmet powders, foodstuff additives, chemical flavors, antibiotics, vitamins, the metals like copper, zinc and aluminum, metal products, sludge and waste water treatment. Standard manufacturing form Structure: feeding pipe, washing pipe,observation window,exhaust hole lightening hole,the sealing structure, rotating drum and outsehll cover machine chassis . all tightening parts are made of stainless seel. transmission and brake:normal motor +friction tyoe automatic clutch +friction type manual brake ItemsmodelsSS300SS450SS600SS800SS1000SS1200Basket Dia(mm)30045060080010001200Basket Volume(L)52040100140230Max. charge(kg)7.53055135200310Rotation Rate of Basket(r/min)28251900150012001000800Relative Centrifugal Force1340910755645560430Power of Motor(kw)1.11.535.57.511Overall Dimensions (l*w*h)(mm)660*650*7601000*750*6301400*1150*8501750*1300*10002000*1550*10002250*1800*1100Weight(kg)1502501000130018002200

Delivery terms and packaging

Packaging Detail: standard wooden case Delivery Detail: 15 days after payment

Port: shanghai port

Payment term

Letter of credit

Telegraphic transfer

Western Union

-

Payment Methods

We accept: